Disclaimer: I am a Senior Citizen with multiple ailments and I have collated articles I have come across over time in this Blog to assist family and friends and Public in general. Having said that These are merely articles published by others and as such I don't take legal responsibility for any of the Contents. It is just for your Reading Pleasure and you decided whether it is Good or Not. Cheers

Search This Blog

Showing posts with label 32 - TECHNOLOGY. Show all posts

Showing posts with label 32 - TECHNOLOGY. Show all posts

Wednesday, October 4, 2017

Friday, April 3, 2015

3-D Printing - Web Med

Watch Video on Original WEbMed Article

http://www.webmd.com/news/breaking-new

When cancer researcher Rosalie Sears, PhD, clicks the print button, ink does not spray onto a page. Instead, actual human cells issue from different heads of her 3-D printer.

In a short while, she has before her a very small tumor -- an exact replica of a patient's cancerous growth. At that point, she and her colleagues can attack the printed copy with any number of cancer treatments.

"The hope is that it will allow us to test, in real time, how a patient's tumor will respond," says Sears, a professor of molecular and medical genetics at Oregon Health and Science University in Portland.

Sears's work is just one exciting aspect of 3-D printing's potential impact on medicine -- from prosthetics, to the bioprinting of cells, to lifelike models of organs, to the possibility of printable, implantable tissue.s/future-of-health/#3d-printing-toc/3d-printing

Creating tailor-made robotic arms and hands is one of the more publicized uses of 3-D printing in health care. Volunteers working with free software available online have designed some of these devices. Such prosthetics are more functional than traditional ones, often at a tiny fraction of the cost. Think $50 vs. $30,000.

"It's more accessible than ever before," says Terry Yoo, PhD, a computer scientist and 3-D printing specialist at the National Institutes of Health. "Today, people are falling over their feet trying to come to the lab to do 3-D printing."

And this is just the start, says Cornell University associate professor of engineering Hod Lipson, PhD, author of Fabricated: The New World of 3D Printing. "The range of materials is expanding, the cost of machines is dropping, and we just keep seeing more and more applications. We haven't seen the least of it yet."

|

Mind-Powered Prosthetic Arms

Les Baugh, who lost both arms in an electrical accident 40 years ago, became the first double shoulder-level amputee to wear and mentally control two modular limbs. He says the device gives him a level of freedom in movement he hasn’t known for decades. The new surgery reassigns nerves that used to control Baugh’s arms and hand, says Johns Hopkins Trauma Surgeon Albert Chi, M.D. The project is still in the early stages of development.

We'll climb the ladder from simple tissue such as cartilage and bone to complex, heterogeneous tissue all the way to functioning organs, which is the Holy Grail indeed."

-Hod Lipson, PhD, Cornell University

Pediatric cardiologist Matthew Bramlet, MD, has already witnessed the benefits of 3-D printing at Children's Hospital of Illinois in Peoria, where he practices. There, surgeons prepare for and plan surgeries for children with complex heart defects with the help of 3-D models of their patients' hearts.

The result? More effective operations. In one case, the model helped surgeons come up with a different way to repair a 3-year-old's heart. The boy -- who was at first expected to live 20 to 30 years -- now might lead a normal life.

"The model allows us to pull [a heart] out of 2-D screen and actually hold it in our hands and evaluate it in a dimension we never had before," says Bramlet. "They are real game-changers."

At Children's National Medical Center in Washington, D.C., engineer Axel Krieger, PhD, also uses his printer to assemble lifelike models of patients' imperfect hearts, using them as both surgical guides and teaching tools. His team has made about 40 model hearts, but a big question remains: Do they improve surgical outcomes? It's too early to tell, Krieger says.

"These surgeries are really complex, and it's difficult to tease out exactly what effect the model has, because it's just one little step in the work flow."

Krieger predicts that they'll have a better idea by next year, after many more heart surgeries.

Cancer researcher Sears also welcomes the ability to go beyond the shortcomings of two dimensions.

Slideshow: How 3-D Printing is Changing Lives

A Helping Hand

Ana Del Hoyo-Quinones was born without a fully formed right hand. Surgeries didn’t help. But last year, e-NABLE, a nonprofit that matches people who need prosthetic limbs with volunteer 3-D printing experts, connected Ana's family to a mechanical engineer near her Colorado home. Clay Guillory and his team gave 31 hours of their own time to design, print, and assemble the plastic layers of Ana’s new hot-pink hand. The whole project cost just $50. After she learns how to write with it, Ana promises she’ll send Clay a thank you letter.

"We can grow tumor cells on a plate in the lab, but that's not how a tumor cell exists in the body, and responses in 2-D don't mimic what we see in the clinic," she says. "That's why we have thousands of targeted therapies that look promising in the lab but don't pan out in clinical trials in patients."

Using mice -- a common tool in cancer research -- also has serious drawbacks. One of them is time. Sears says it takes 6 months to implant and grow a tumor in a mouse. For fast-growing cancers like pancreatic cancer, patients can't wait that long. Enter 3-D printing or, more accurately, bioprinting, because this involves human cells.

"Within two weeks, we can learn whether these printed tumors respond or don't respond to a given therapy," Sears says.

Another advantage: Sears can print numerous identical tumors at the same time, allowing her to test multiple drugs at once.

"It's very exciting, both in terms of potentially getting patients the right drugs sooner and in understanding how cancer cells communicate with other cells," she says. "It's more promising to me than anything else that's out there right now."

But she says much research still needs to be done. The big question: Will patients' tumors respond to drugs in the same way as the 3-D printed models?

To Lipson, research such as Sears's is just the first step in 3-D printing's most exciting direction.

Video: 4-D? Printing Enters a New Realm

4-D? Printing Enters a New Realm

Which body part can't be replaced or enhanced with a 3D printed implant?

Skull

Windpipe

Achilles tendon

Backbone

Submit

"That's the ultimate: bioprinting, or printing with live cells," Lipson says. He predicts we'll start to go beyond model making within the next several years. The next stop: implantable 3-D-printed tissue.

"I think that that is where the future is," he says. "We'll climb the ladder from simple tissue such as cartilage and bone to complex, heterogeneous tissue all the way to functioning organs, which is the Holy Grail indeed."

Lipson thinks FDA approval for the first such procedures remains at least 5 years away, though lab and animal testing is ongoing.

Interesting ethical questions come with the advancing technology, he says. For example, if scientists can bioprint a new knee to replace one ravaged by arthritis, do you go with a copy of your old knee, or do you allow a computer to design you a better one? Can we rebuild or improve our bodies?

In the short term, Lipson says, we'll see more and more 3-D-printed synthetic implants, such as hip and other joint replacements, custom-shaped to improve how well they work. Unlike prosthetics, though, implants can be costly.

"They're already on the market, but they're fairly new and expensive," he says.

Lipson says new developments in 3-D printing will be determined by economics: "It's a question of funding and market priorities rather than purely a technical challenge."

But we should expect big things, he says. "This is just the beginning. There's a lot more to come. This is not just a hype cycle."

Share This:

By Matt McMillen

Reviewed by Brunilda Nazario, MD on January 16, 2015

Sources

©2015 WebMD, LLC. All rights reserved.

|

Labels:

32 - TECHNOLOGY

Friday, March 20, 2015

A True Revolution in the World of Medicine

|

A brand new medical scanning technology has recently been introduced, providing amazingly-detailed images and a level of speed and accuracy never seen before. This technology allows doctors to quickly and accurately diagnose patients. It's called Revolution CT, and for good reason.

In the early 1970’s, the first commercial Computer Tomography (CT) scanner began operating in the United Kingdom. The machine used a basic computer to record a set of 160 parallel readings in an 180° view. The process took many hours but provided better results compared to old X-rays. By the 1990’s it became fast enough for a scan to take about 30 minutes or so.

|

|

|

|

|

|

Typical CT machine and CT results sheet

|

|

|

Introduced in the early 1980’s, Magnetic Resonance Imaging (MRI) scans, which uses magnetic fields to map the body, eliminated the need for radioactive X-rays (though the use of magnetic fields has been shown to have its own set of health dangers). The newest, fastest MRI scanners take about 40 minutes to complete a scan, but operational costs are considerably higher compared to CT. Until today, when doctors wanted higher accuracy, and really good imaging of the human body - they turned to MRI scans. That is, until 2013.

|

|

|

|

|

|

An MRI machine and typical MRI scan results

|

|

|

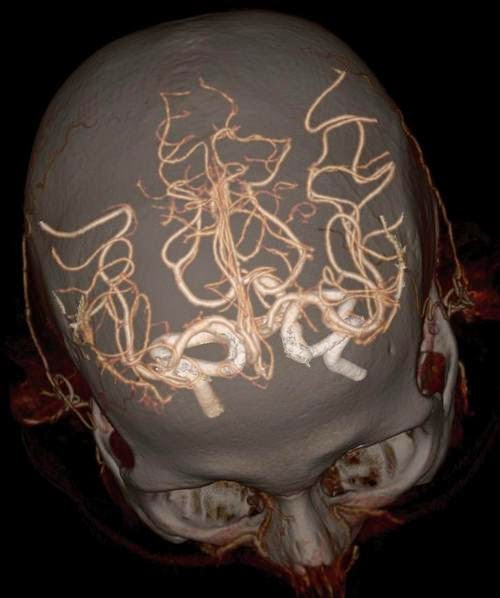

In 2013, General Electric introduced the new technology called Revolution CT, which is not only considerably faster, but more importantnly produces much higher-resolution images than the conventional CT and MRI. The scans are performed by a computerized system that creates detailed 3D images of the necessary organs, bones, blood vessels, and even soft tissue.

|

|

|

|

|

|

A high-definition image of the skull and the Circle of Willis, the blood vessel system supplying blood to the brain.

|

|

|

The system’s computer can perform motion correction, saving the need for the patient to be perfectly stationary, the process is fast and relatively silent, and the device itself is far less intimidating than classic CT and MRI machines.

|

|

|

|

|

|

A high-definition musculoskeletal image of a foot and ankle reinforced with plates and screws.

|

|

|

Clinical trials have yielded highly accurate results, allowing doctors to diagnose patients correctly with ease, while still minimizing their exposure to X-rays.

Have a look at these incredible images below to see the level of detail of the Revolution CT:

|

|

|

|

|

|

An image of the abdomen and the aorta.

|

|

|

|

|

|

|

|

|

The whole aorta and kidneys.

|

|

|

| |

|

A high-definition image of the skull and the Circle of Willis.

|

|

|

|

|

|

|

|

|

The Circle of Willis.

|

|

|

|

|

|

|

|

|

A high-definition image of the skull and the Circle of Willis.

|

|

|

|

|

|

|

|

|

The skull and carotid arteries.

|

|

|

|

|

|

|

|

|

An image of the abdomen and pelvis.

|

|

|

|

|

|

|

|

|

The rib cage, the heart and the chest cavity.

The Revolution CT can image the heart in a single heartbeat.

|

|

|

|

|

|

|

|

|

An image of the human heart with stents typically used to treat narrow or weak arteries.

|

|

|

|

|

|

|

|

|

The chest cavity with a side view of the heart.

|

|

|

| |

|

The pelvis and the aorta.

|

|

|

|

|

|

|

|

|

The whole aorta and kidneys.

|

|

|

|

|

|

|

|

|

An ankle reinforced with screws.

|

|

|

Image Credits: GE Healthcare

|

|

Source: Darel S.

Labels:

01 - GENERAL,

32 - TECHNOLOGY

Wednesday, July 16, 2014

Monday, March 24, 2014

3D-Printed 'Bionic' Ear Can Hear Beyond Human Ability

Scientists at Princeton University have designed a bionic ear that can hear better than human ears. And get this: It was printed using an off-the-shelf 3D printer.

We've heard of 3D printers someday building human organs before, but what's noteworthy about this project is this printed ear intertwines embedded electronics. These Princeton researchers basically 3D-printed cells and nanoparticles, and then combined a small coil antenna with cartilage to create this "bionic" ear, according to the university.

The result was a fully-functional organ that can hear radio frequencies a million times higher than our human ears, lead researcher Michael McAlpine told Mashable.

"The way that our ear hears now is we pick up acoustic signals and then we convert those into electrical signals that go to our brain," said McAlpine, who is an assistant professor of mechanical and aerospace engineering at Princeton. "What this ear does is it has this electronic coil on it and it picks up electronic signals directly."

McAlpine said he and his research team basically wanted to ask the question of whether they could grow an organ in a petri dish, with the electronics intertwined into the organ as it grew. Their successful project used a $1,000 3D printer to print the cells with the electronics (see video below). The "ear" was then put in a dish so the cells could culture for 10 weeks into cartilage tissue.

Labels:

01 - GENERAL,

32 - TECHNOLOGY

Subscribe to:

Posts (Atom)